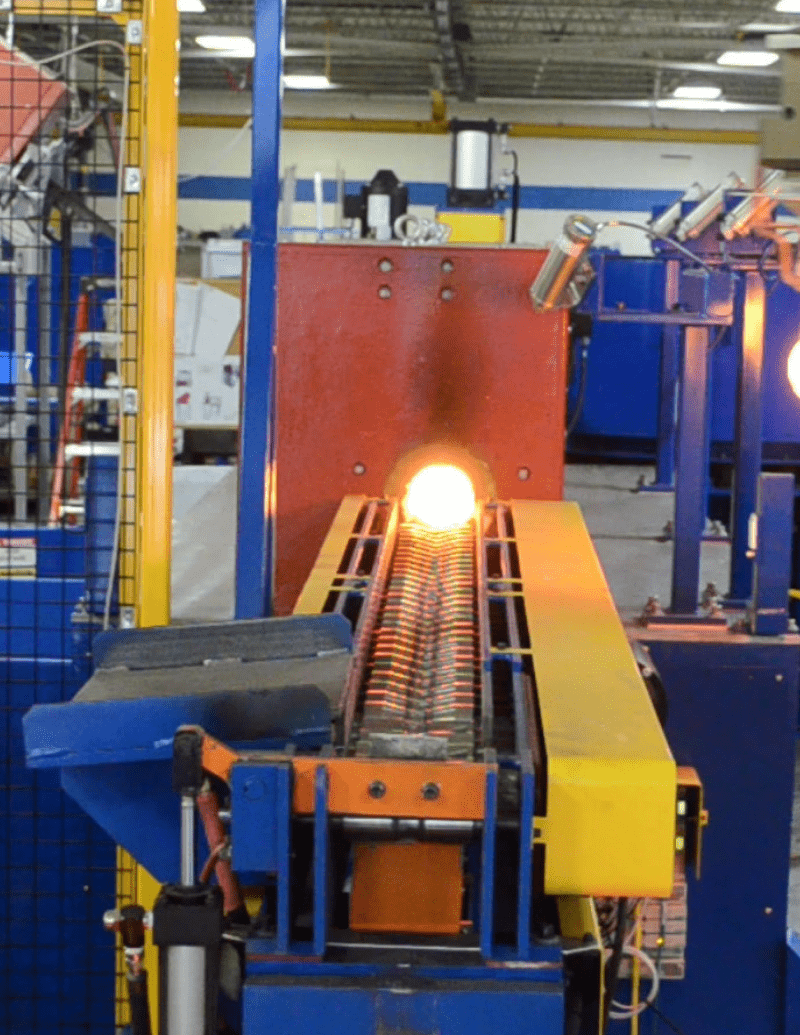

billet heating

General Information

Billet Heating Machines

Interpower Induction billet heaters are designed to heat any dimension of billets and slugs in materials as diverse as stainless steel, copper, aluminum, titanium and brass.

Power ranges vary from 6 kW up to several MW, at frequencies of 500 Hz – 50 kHz. All our billet heaters feature Interpower Induction power converters, which are available in IGBT transistor versions. Our billet heaters can be fitted with a range of tipper, loader, feeder, extractor and other options.

Compact and separate cabinet systems are available. In compact models, the Sinac and the heater are housed in a single cabinet. In separate versions, they are housed in two different cabinets.

Interpower Induction’s Forge-Link™ controls package is the most advanced operator interface available today. This interface allows the customer to enter billet information (diameter, length, rate, and temperature) directly at the machine HMI and from that the system runs the most efficient power distribution available. There is no need to do anything “off line”, and it is capable of automatic compensation while running.

Designed to match your billet containers, the tipper can be combined with a vibratory channel for smooth loading.

Various loaders are available to match blank sizes and planned throughput volume. The heaters can be fitted with single- or multistair hopper loaders, vertical sorting conveyors, vibratory bowl or robot arm.

Each coil is fastened to an insulating beam for stable positioning. The coils are coated, and thermally protected by casted refractory concrete.

The heated billets are immediately extracted and sorted by temperature following a temperature reading by a pyrometer. The exactor can be easily removed when processing short billets.

Looking For A Solution to Your Project Challenge?

NORTH/SOUTH AMERICA

Interpower Induction

3578 Van Dyke Ave. Almont, MI, 48003

+1 (810) 798-9201

Email

Interpower Induction Services

34197 Doreka Fraser, MI, 48026

+1 (586) 296-7697

Email