zone control technology

General Information

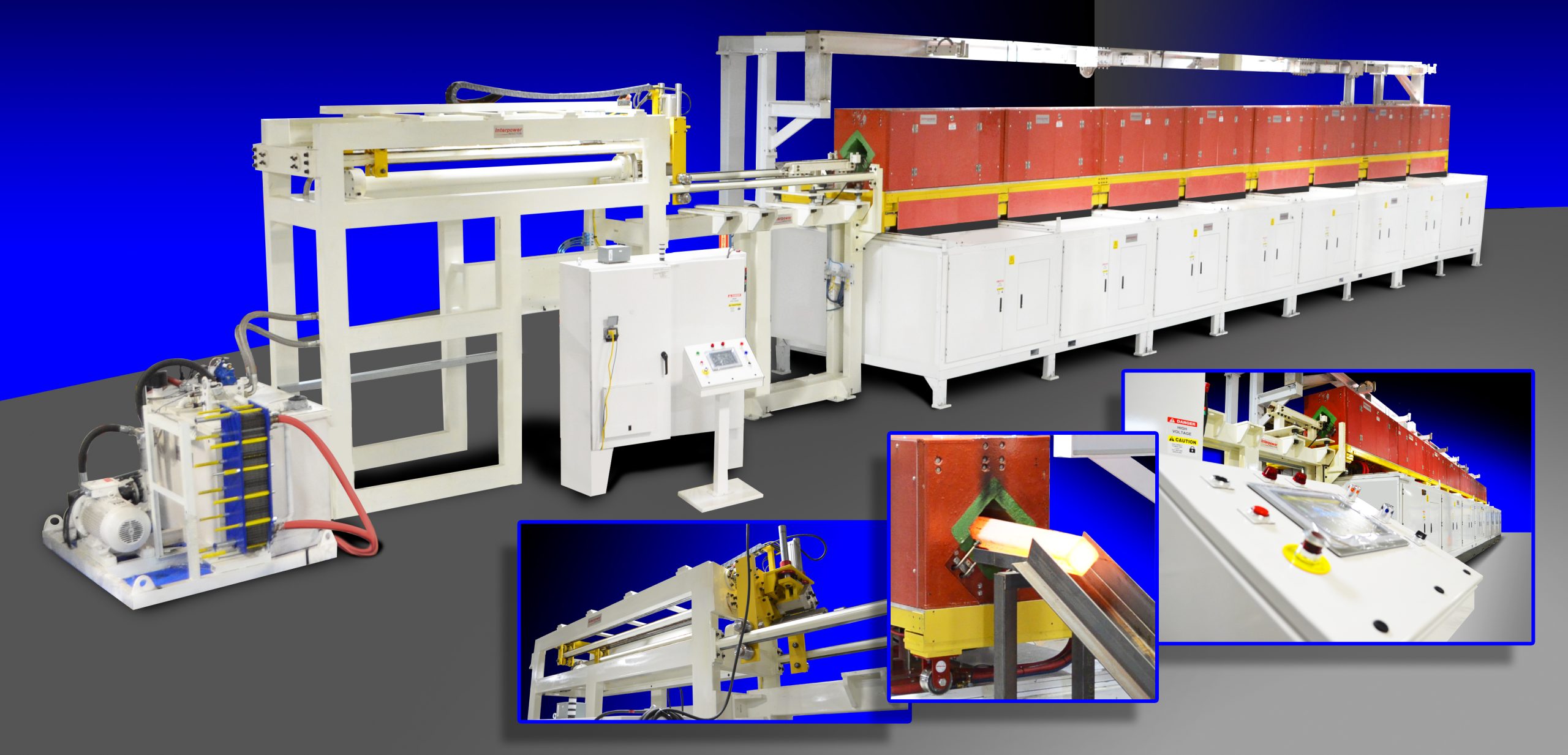

Interpower Induction was the first company to invent and offer Zone Control technology for billet heating more than 15 years ago. Zone Control allows the power to each coil to be individually controlled to maximize efficiency and minimize loss of heated billets.

Zone Control Systems have been perfected by Interpower Induction to meet plant size and heating applications. Instead of one large power supply inverter with the output power distributed across an entire coil line, the large inverter is broken down into sections and each section is connected to a coil. Power is managed to optimize the usage across the line and advanced operational features are enabled. There are significant energy savings from this improved process.

Zone Control Technology Advantages

MAXIMIZE EFFICIENCY

The ideal coil line length, when run at a given production rate and billet dimension, maximizes system efficiency. We have measured over 7 pounds per kilowatt (3.2kgs-kW) with this technology verses 5.5 pounds per kilowatt for a conventional type induction heater.

FLOOR SPACE

Shorter coil line lengths reduce the floor space requirements while maximizing surface to core uniformity.

FLEXIBILITY

Systems can be designed for future additions or subtractions of “Zones” so customers can purchase cost effective additions with energy efficient options for future capabilities.

REDUCTION OF COIL SPARES

Every coil on the line can be placed in any position. There are no unique coils and therefore a reduction in the number of coil spares.

IDEAL STARTUP & HOLD MODE

After a day-long run, it’s common that the line will be full of billets. The next day, the system may be started and the coil line will not begin to move until each zone has reached the appropriate temperature. The last coil on the line is turned on first, followed by the next coil back, until the first coil on the line is turned on. This will minimize the number of under heated billets that get rejected. The coil line can be stopped during a hold. Upon restart, there is a minimum loss of heated billets.

Looking For A Solution to Your Project Challenge?

NORTH/SOUTH AMERICA

Interpower Induction

3578 Van Dyke Ave. Almont, MI, 48003

+1 (810) 798-9201

Email

Interpower Induction Services

34197 Doreka Fraser, MI, 48026

+1 (586) 296-7697

Email