robotics

General Information

Interpower Induction utilizes robotic automation for several different machine types. From forging to heat treating, robotic automation will help you reduce down time, increase efficiency and ultimately, raise your ROI.

In-feed automation systems are used to transfer billets into; and through heating systems. These will typically include mechanisms that can drive a series of billets through the induction coils with controlled feed rates and consistency. This automation is usually an integrated function of the heating system but can also be retrofitted into older forging systems.

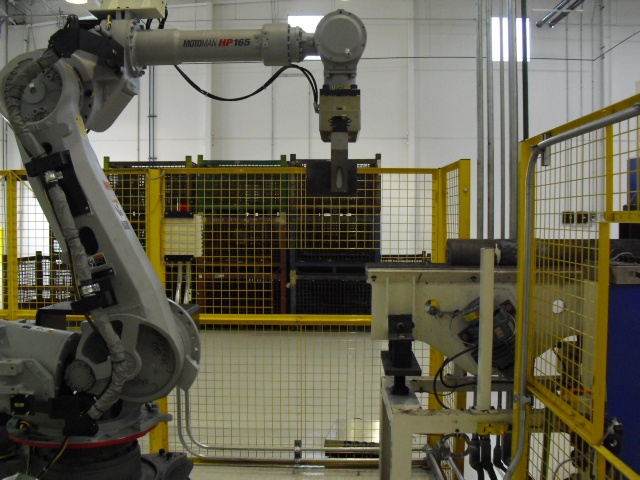

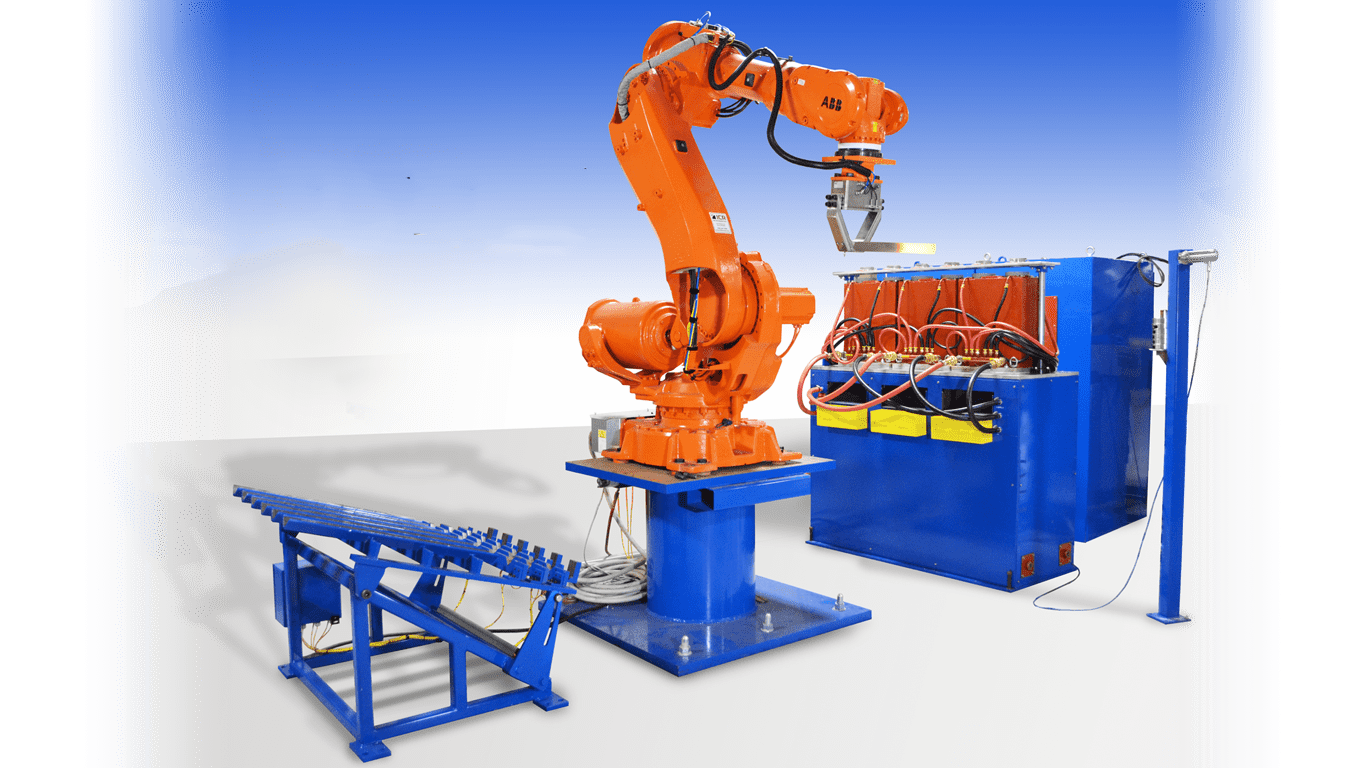

Robotic Loading/Unloading

The world of robotic handling offers manufacturers a new era of automation. Robots offer great alternatives in the area of pick and place processing by adding the ability to have six-degrees of movement, to pick from multiple positions, transfer to multiple positions, re-orient the part during transfer, load and unload inspection stations along the way, and pick billets directly out of a container. The return on investment is more than justifiable.

Companies can further customize and tailor the loading and in-feed process for an ever-changing product stream. Robots are being used to quickly extract hot billets and deliver them to the next process after the induction heater. Many companies are also using robots to transfer parts to presses and actively forge the parts in the press.

Some advantages of using robotics in the forging process include the following:

- Rapidly reduce worker fatigue, injuries

- Reduction in machine down time

- Six-Axis Part Manipulation replicating same movements as operator

- ROI – Robots can be multi-purposed across multiple projects with re-programming

- Repeatable movements and cycle times in the manufacturing process

- Ability to handle “hot parts” coil unload to press load

- Increased worker safety & ergonomic handling of heavier billets

- Addresses the problem of finding skilled labor & training cost

- Efficient manipulation & handling of parts

- Reduced loading times

- Consistent cycle time from heating to press operations

- Repeatability in the heating/movement process to assure metallurgical properties are being maintained

- Increased quality measures to assure only correct billets are processed

Robotic Automation for Induction Heating

BAR END HEATING

BILLET HEATING

BAR HEATING

QUENCH & TEMPER

BRAZING

HARDENING & TEMPERING

Looking For A Solution to Your Project Challenge?

NORTH/SOUTH AMERICA

Interpower Induction

3578 Van Dyke Ave. Almont, MI, 48003

+1 (810) 798-9201

Email

Interpower Induction Services

34197 Doreka Fraser, MI, 48026

+1 (586) 296-7697

Email